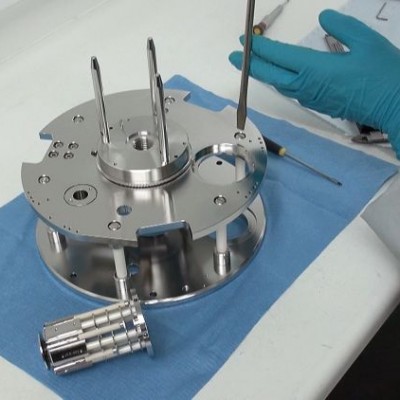

To complement our machining facilities, J.E.B. Precision also offer clean assembly services. Manufactured components are cleaned and assembled with bought out / free issue parts to customer’s Bill of Material in a clean environment.

We have many years experience in the supply of component sub-assemblies to the scientific instrument sector. Our machining and clean room assembly facilities are setup for delivering regular monthly call offs or to Kanban (JIT) requirement. Components are cleaned in our 7 stage aqueous ultrasonic system.

In addition to machining and assembly facilities, J.E.B. Precision also have Tig Welding and vacuum leak checking equipment.

Single Source Supply

The combination of clean assembly and welding / vacuum leak checking facilities provide a one stop shop for the scientific instrument and vacuum science industries, thus eliminating the problems associated with multi sourcing of piece parts.